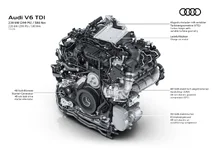

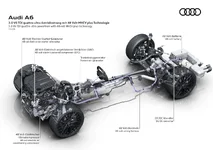

Audi is expanding its engine lineup for the Audi Q5 (combined fuel consumption in l/100 km: 6.8–5.8 (34.6–40.6 US mpg); combined CO2 emissions in g/km: 177–153 (284.9–246.2 g/mi); CO2 class: G–E) and Audi A6 (combined fuel consumption in l/100 km: 6.1–5.3 (38.6–44.4 US mpg); combined CO2 emissions in g/km: 165–140 (265.5–225.3 g/mi); CO2 class: F–E) with a three-liter V6 diesel engine delivering 220 kW (299 PS) and 580 Nm of torque. For the first time, the MHEV plus technology, which delivers up to 18 kW (24 PS) of additional power, is being used in combination with an electrically powered compressor. The engine therefore sets new standards compared to its predecessors. The interaction of three electrified components ensures immense driving fun and highly efficient performance. The V6 TDI quattro can now be ordered for both models.

- New evolution of the V6 TDI with MHEV plus technology and electrically powered compressor

- Hybrid powertrain with three electrified components for powerful performance off the line and high efficiency

- Faster boost pressure buildup enhances power delivery; sustainable HVO 100 fuel reduces CO2 emissions

The belt alternator starter’s primary function is to start the engine and supply the battery with electrical energy. The powertrain generator enables partially electric driving, which means that in slow city traffic, when parking and maneuvering, and in steadily moving traffic on roads outside of towns, the vehicle operates purely electrically. The powertrain generator also provides an additional 230 Nm of drive torque and up to 18 kW (24 PS) of power when starting off and overtaking. When decelerating, it feeds up to 25 kW of energy back into the battery.

Hybrid powertrain combines three electrified components

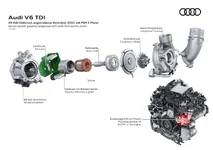

In the enhanced three-liter V6 TDI, the MHEV plus technology is now being expanded to include an electrically powered compressor for the first time – a technological leap that enables the perfect balance between a dynamic driving experience and optimized fuel consumption.

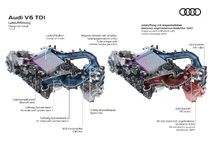

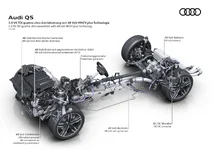

At the same time, the electrically powered compressor is an integral part of the engine management system and the newly developed combustion strategy. It supports the turbocharger in a two-stage charging concept with maximum precision. In combination with the MHEV plus electrification consisting of a belt alternator starter and powertrain generator, the V6 TDI engine EA897evo4 delivers powerful performance in every driving situation: when starting from a standstill, accelerating out of town, overtaking, and driving on the highway.

The electrically powered compressor overcomes turbo lag, providing high torque values at low engine speeds. This results in significantly lower fuel consumption compared to the previous engine generation. Responsiveness during initial acceleration has also been substantially improved: in the first 2.5 seconds, the vehicle covers a good car length more. While the belt alternator starter starts the engine and supports it as it builds revolutions, the powertrain generator and the electrically powered compressor provide torque for acceleration. In this process, the electrically powered compressor amplifies the increase of boost pressure. At the same time, the powertrain generator transmits the first direct torque impulse to the wheels.

New electrically powered compressor delivers impressive mid-range acceleration and linear response

The electrically powered compressor is located behind the conventional turbocharger and the intercooler in the intake path. It is powered by the 48-volt onboard electrical system. When the load demand from the accelerator pedal is high, and the energy supply on the turbine side is low, the intake air is directed to the electrically powered compressor. There, this air – already compressed by the exhaust-driven turbocharger – is further compressed before entering the combustion chamber.

Compared to earlier models equipped with an electrically powered compressor, such as the S4, S6, and SQ5, the current generation is significantly more powerful – thanks to a wider operating range and faster buildup of boost. This is made possible by the optimized airflow design of the compressor and the permanent-magnet synchronous motor that drives it, in combination with improved air supply to the six cylinders.

Whereas the electrically powered compressor previously operated only within a narrow range, the new generation now functions across the entire engine speed range. This system ensures a linear and fast response, impressive mid-range acceleration with even more direct pedal feel, increased efficiency, and improved long-term durability.

Through the interaction between the electrically powered compressor and the powertrain generator, maximum boost pressure of 3.6 bar builds up nearly one second faster – delivering noticeably enhanced acceleration experienced without turbo lag. It closely resembles the feel of an electric drive with similar power. During acceleration, the compressor wheel spins up to 90,000 revolutions per minute in just 250 milliseconds, an increase of nearly 40 percent.

As a result, the V6 TDI engine EA897evo4 puts its power to the road with authority – made possible by the blend of electric boost and impressive power output of the diesel engine.

Sustainable fuel: HVO 100 reduces CO

The new V6 TDI is approved to use HVO fuel conforming to European standard EN 15940 – indicated by the XTL sticker in the fuel tank cap. XTL (X-to-liquid) is a collective term for fuels of this standard, with the “X” representing a variable source component. HVO stands for hydrotreated vegetable oil. This sustainable fuel enables a 70 to 95 percent reduction in CO2 emissions compared to petroleum-derived diesel.

HVO is produced using residual and waste materials, such as used cooking oil from the food industry or agricultural by-products. Using hydrogen, the oils are converted into saturated aliphatic hydrocarbons. This modifies the properties of the vegetable oils to make them suitable for use in diesel engines. They can be blended with conventional diesel to replace fossil components or used as a 100 percent pure fuel. New vehicles leaving the two German Audi plants in Ingolstadt and Neckarsulm are delivered with HVO fuel already in the tank.

The technical animation for the V6 TDI can be found here

read on

Audi MediaCenter