- New pioneering technology programme focused on decarbonising all vehicle components and materials

- More than 40 new component and material concepts undergoing research and development show enormous potential to significantly reduce a vehicle’s carbon footprint and substantially increase the share of secondary materials

- Rethinking component design: headlight engineered for circularity and new joining technology

- Innovative thinking that accelerates mono-materials and increased use of recyclates

- Focus on fossil-free through evaluation and development of bio-based and bio-circular alternatives

- Ensuring the Mercedes of today is a valuable source of raw materials for the Mercedes of tomorrow

“There can be no doubt that the overriding goal for all our products is to excite our customers while decarbonising the automobile, driving down resource use and growing the circular economy. Innovation is a key route to achieving this and Tomorrow XX makes clear the huge strides we are taking. Together with our suppliers and partners, we are leading the way and embedding sustainability deep into our operational business and along the entire supply chain.”

Olaf Schick, Member of the Board of Management Mercedes-Benz Group AG.

Integrity, Governance & Sustainability

“Mercedes‑Benz has always been an innovation powerhouse. With our ‘Design for Environment’ and ‘Design for Circularity’ approaches, we are rethinking literally every single component from scratch. The Tomorrow XX technology programme pushes this holistically across our entire product portfolio and value chain to the limits of what is possible. More than 40 new and more sustainable component and material concepts in just two years is a phenomenal result and a taste of the enormous potential we are unlocking.”

Jörg Burzer, Member of the Board of Management of Mercedes-Benz Group AG.

Chief Technology Officer, Development & Procurement

Tomorrow XX: reduce carbon emissions, increase recycled content, build a circular economy

The Tomorrow XX technology programme pursues a collaborative and interdisciplinary approach. Mercedes‑Benz development experts work closely with partners along the entire value chain, including recycling companies and start-ups. The aim is to put all components and materials under the microscope – from the battery to the bodyshell and from interior equipment to trim. Even materials hidden from view such as insulation are closely examined. Every kilogram of CO₂ is scrutinised and questioned. The questions are: Which components need to be redesigned to make them easy to dismantle, repair and recycle? Which materials need to be changed, recombined or replaced to reduce CO₂ emissions, use fewer resources and be recyclable? Which primary materials can already be replaced today by recyclates? In Kuppenheim (southern Germany), Mercedes‑Benz is accelerating the construction of its own in-house pilot recycling plant for batteries to completely close the material loop. The facility is currently in the research and development phase, with the target of establishing a forward-looking und sustainable solution for battery recycling.

With Tomorrow XX, the company has already identified more than 40 new, more sustainable components and materials in approximately two years. Together, they have the potential to further significantly reduce the carbon footprint of a future series-production vehicle relative to the current portfolio and to substantially increase recycled content. Measures include new and optimised material cycles. Development of the new concepts took into account stringent Mercedes‑Benz standards in respect of quality, design and comfort. The consistent goal is to implement sustainability. The spectrum ranges from disruptive ideas at an early stage of development to concepts that are close to series production and innovations already in series production.

Rethinking component design and material combinations

Tomorrow XX stands for the holistic Mercedes‑Benz “Design for Environment” approach aimed at reducing both carbon footprint and the consumption of primary resources. From the earliest stages of product development, experts are rethinking the use and composition of all materials. The goal is to embed requirements concerning environmental and climate protection into vehicles from the very start.

Within this, Mercedes‑Benz is pursuing the principles of the circular economy (Design for Circularity). The company is developing vehicles in a way that minimises the consumption of finite resources, maximises the proportion of recycled materials and reduces waste. At the end of a vehicle’s life, Mercedes‑Benz wants to close the loop and return as many recyclable materials as possible to the system. The prerequisite for material recycling is ensuring that components are easy to dismantle and that different materials can be separated by type. So-called mono-materials are better because they do not require separation prior to recycling, making them a valuable resource for new products. Material mixtures, on the other hand, are much more difficult to recycle, meaning some are only thermally recycled.

Making the inseparable separable: the headlight re-engineered for circularity and a new joining technology

Mercedes-Benz is working to change the design of highly complex components to make them quick and easy to disassemble into their individual parts. A promising Tomorrow XX research project is a recyclable headlight. The various components such as the lens, cover trim and frame, housing and electronics are screwed together rather than glued (today’s standard practice). Consequently, they are quick and easy to separate without damage. This means individual components can be replaced, making a modern headlight repairable for the first time. Following a stone chip, for instance, there is no need to replace the entire headlight, just the lens. For customers, this could make repairs more efficient in future.

The headlight’s longer service life could conserve resources and avoid carbon emissions. Another advantage is that the headlight would be better for recycling. This is because the individual modules are each made of just one material, which makes them easier to sort and highly efficient to recycle. Looking to the future, this mono-material design should make it possible to use more recycled material and to source a large part of that from old headlights. The proportion of secondary materials could potentially be almost doubled compared to today’s headlights, while carbon emissions could be almost halved.

A similarly complex component is the interior door panel. It consists of different parts joined by ultrasonic welding. Mercedes‑Benz has developed a new joining technology that makes separating the individual materials better and easier. The adapted thermoplastic rivet is now easy to undo, allowing faster separation of the individual components without damaging them. Optimising dismantling in this way also simplifies repair and improves recyclability. The new technology could potentially replace a large number of thermoplastic joints in the interior.

Accelerating use of mono‑materials and recyclates

On average, a modern Mercedes‑Benz contains around 250 kilograms of plastic. Many of these components consist of mixed plastics, which can only be mechanically recycled to a limited extent and are therefore often thermally recycled. Recovering them for use in high-quality products is usually not possible. The Tomorrow XX technology programme focuses on accelerating the use of mono-materials, while also replacing primary resources with secondary materials.

Innovative PET mono-sandwich halves carbon footprint of a door pocket

For a number of interior components, Mercedes‑Benz has developed a sandwich composite system that consists of only one plastic: recycled PET. The basis is a foam core with a bone-like structure. This reduces the weight of a door pocket by more than 40 percent compared to the previous material system made of primary plastic. The performance of the part remains the same. The outer layers consist of an innovative mixture of PET fibres, giving the composite system the necessary rigidity. The innovative PET mono-sandwich combines lightweight design, recycled materials and circularity with cost-effective process technology. In 2024, it was awarded the internationally renowned Materialica Award in the category “CO₂ Efficiency” and will soon enter series production.

Because PET is highly suitable for recycling, it offers great potential to replace primary materials in vehicles. For many years, Mercedes‑Benz has used seat covers and wheel-arch liners made from 100-percent recycled PET bottles. Right now, the company is also working on carpet and floor mats made entirely from PET with a high recycled content. This could reduce the carbon footprint of carpet and floor mats by up to 75 percent.

Mercedes‑Benz wants to drive up its use of pre- and post-consumer recyclates (PCR) available on the market. For example, the all-new CLA has a wiper fluid tank made from 100-percent recycled instead of primary polypropylene. Components such as front and rear bumpers could also contain up to 25 percent PCR.

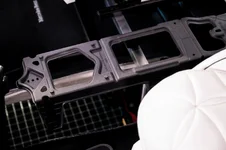

New approaches in aluminium production with up to 86-percent secondary material

Aluminium plays a central role in vehicle architecture. However, the production of this material is one of the most energy-intensive industries in the world. To significantly reduce its emissions in the long term, Mercedes‑Benz is working with technology partners to pursue multi-stage transformation across the entire value chain. The company promotes the use of intelligent solutions and technologies through multi-year purchase agreements as well as close collaboration in material research and development.

Mercedes‑Benz is working with all partners to keep driving down carbon emissions and is making the switch to alternative energy sources part of its procurement criteria. 40 percent of the aluminium for the new CLA is already produced in electrolysis plants using renewable energies. This delivers a reduction of around 400 kilograms of CO₂ per vehicle in comparison to the preceding non-electric model. In addition, Mercedes‑Benz is already using low-carbon aluminium in series production. Sourced from strategic partner Hydro, it has 70-percent fewer CO₂ emissions than the European average. By 2030, the partners want to reduce the carbon footprint even further – by around 90 percent. In addition, Mercedes‑Benz is injecting crucial momentum into the transformation of aluminium production: In close dialogue with its partners, the company is driving the introduction of innovative technologies. In future, these will replace the carbon-based anodes currently used in the electrolysis process, which are a source of emissions.

Another lever is the use of high-quality recycled material, which reduces the need for energy-intensive primary aluminium. This is an important factor in the circular economy for materials. A promising example is an aluminium side wall containing up to 86-percent post-consumer scrap from sources such as old wheel rims, window frames and scrap vehicles. The material properties and surface finish remain the same.

On the road to almost zero-carbon steel

Alongside aluminium, steel is a material that is likewise carbon-intensive to produce. That’s why Mercedes‑Benz is targeting innovative technologies and partnerships with leading steel manufacturers. The focus is on processes that can avoid greenhouse gas emissions almost completely. The core of this development is the replacement of the classic blast-furnace route. The alternative combines hydrogen-based direct reduction with the use of electric-arc furnaces and a higher scrap content. If this process is powered entirely by renewable energy, CO₂ emissions can be reduced to a minimum, resulting in virtually zero-carbon steel. Mercedes‑Benz has already concluded agreements with various partners.

On the way there, Mercedes‑Benz is already using steel products in series production that have a scrap content of 100 percent and are manufactured in electric arc furnaces. This reduces the CO₂ footprint by more than 60 percent compared to the classic blast furnace route. Mercedes‑Benz is working consistently to increase scrap rates, even for more complex components.

Steel used for components that are visible to customers has the most demanding surface-finish requirements. Currently, this is produced primarily using 16- to 25-percent pre-consumer scrap content. Tests with material containing a proportion of post-consumer scrap are currently delivering very promising results. This specially processed post-consumer scrap comes exclusively from end-of-life vehicles.

Urban mining turns today’s Mercedes into a valuable source of materials for tomorrow’s Mercedes

At the end of their life, materials should not be a problem but a resource. Mercedes‑Benz therefore wants to use end-of-life vehicles strategically as an urban source of raw materials. The company wants to close value chains and recover secondary raw materials for use in new Mercedes‑Benz vehicles. Together with its partner TSR Group GmbH & Co. KG, Mercedes‑Benz launched a pilot project for urban mining in the summer of 2025. An innovative take-back site for disused vehicles is being built in northwestern Germany. The pilot project provides important insights for the scaling and integration of post-consumer materials in future models. It can make a significant contribution to securing recycled raw materials for reintegration into the product cycle.

As part of the Tomorrow XX technology programme, Mercedes‑Benz and its partner companies are already working on a large number of new concepts. Together, they are seeking to replace existing materials with post-consumer recyclates from end-of-life vehicles – and thus close the company’s own material loops.

New life for old tyres with high-quality leather alternative and acoustic absorbers

Scrap tyres offer great potential. First, a chemical recycling process converts them into pyrolysis oil, which can be combined with certified biomethane from agricultural waste. Both raw materials are then processed into plastic according to the mass balance method[2].Thisinnovativerecycledplastichasthesamepropertiesasvirginplasticmadefromfossil-basedraw materials.Thismakes it suitable for useasashort-term drop-insolutionfor current series production.Atthesametime,itmeets Mercedes‑Benz 's strictqualityrequirements–especiallywithregardtopaint finishandcrashsafety. Mercedes‑Benz hasalreadyintroducedthefirstcomponentmade from thisinnovativerecycledplastic (a pull-out door handle) inseveral models.

With the help of biotechnology, the plastic recyclate based on old tyres can also be used to produce a high-quality leather alternative. Combining it with bio-based proteins creates an innovative material that resembles real leather in composition and structure. It can also be processed using conventional retanning methods. This not only enables a very high-quality look and feel, but also excellent technical properties. Its maximum tensile strength is twice that of genuine leather, it is extremely temperature-resistant and at the same time breathable, waterproof and significantly lighter. Compared to real leather, the carbon footprint is around 40 percent lower. Plus, the content based on plastic recyclate can be recycled again.

In addition to chemical recycling, used tyres can also be mechanically recycled. Mercedes‑Benz is working on producing absorbers from shredded old tyres, with one possible use for their fibres being acoustic insulation. These absorbers are welded directly onto the underbody cladding as vibration dampers. A small proportion of BiCo fibres (multi-component polymer fibres) gives the fibre composite its necessary stability. The rubber particles from the old tyres in the absorber matting have no negative effects. On the contrary, they enhance the insulation performance.

Valve casing and engine mounts made from recycled airbags

Airbags are made of fibreglass-reinforced polyamide, which can be easily recycled. The Tomorrow XX technology programme has already identified and tested two components that could be made from recycled airbags. These include engine mounts and the sophisticated valve housing in the thermal management system. It must withstand high pressures of 0.01 to 5 bar and extreme temperatures from -40 to +130 degrees Celsius. This shows how it is possible to turn high-quality materials into new high-tech vehicle components.

Underbody cladding made from recycled mixed plastics from scrap vehicles

Anotherinnovative solutionisunderbodycladding made with plasticsfromscrapvehicles that are completely recycled.Thesemixedplasticscome fromtheso-calledshredderresidue produced whenend-of-life vehicles are recycled.Itisamaterialstreamthatiscurrentlypredominantlythermallyrecycled. Mercedes‑Benz wantstobringitbackintothematerialloopasasubstituteforvirginplastics.Thiscouldreducethecarbon footprintoftheunderbodytrimbyup to40percent.

This recycled material could potentially be used for black plastic parts subject to low loads. The use of recycled glass fibre here is also under investigation. With 100-percent post-consumer plastic recyclate based on end-of-life vehicles, the innovative underbody cladding perfectly embodies the concept of the closed material loop. It was awarded the prestigious Materialica Award in the “Process” category in 2025 – and is about to go into series production.

Recycled brake pads could cut CO₂ emissions by up to 85 percent

Mercedes‑Benz has been operating its own take-back system for friction components (MeRSy) for many years and is thus able to recycle parts from its network. As part of Tomorrow XX, Mercedes‑Benz R&D has developed a brake pad concept in cooperation with suppliers. The new brake pads contain around 40-percent waste from old brake pads. At up to 85 percent, the CO₂ savings for this highly complex material mixture are particularly interesting. The component is paired with a back plate made of CO₂-reduced steel. This is just one example of how Mercedes‑Benz is reducing CO₂ emissions for individual components through the optimisation of material composites.

Lower carbon emissions in the battery cell value chain by more than 70 percent and significantly increase recycled content in the supply chain

The battery is the central component of an electric vehicle – and also the one with the highest carbon footprint. Mercedes‑Benz is therefore pursuing a holistic, multi-stage transformation approach to decarbonising the battery cell supply chain. The first lever lies with the direct suppliers who produce battery cells. Cell manufacturers contracted by Mercedes‑Benz are committed to using green electricity in their production facilities to implement energy-efficient processes and continuous emission reduction. Mercedes‑Benz is also working with specialist partners to convert electrode production processes to green electricity and to integrate innovative technologies.

To actively accelerate the decarbonisation of cell production, Mercedes‑Benz is applying further specific measures. For example, it is researching dry coating as a forward-looking technology. It replaces energy-intensive drying with hot air and offers considerable potential for carbon reduction, especially in electrode production (cathodes in particular). These cell components are crucial for battery performance, but also for its carbon footprint. Plus, this pioneering technology dispenses entirely with the need for environmentally sensitive additives such as NMP (N-methyl-2-pyrrolidone).

Another lever is the increased use of secondary (recycled) cathode and anode materials in the cells. Mercedes‑Benz is working with its partners on battery cells made with maximum recycled content in their anode and cathode materials. In addition, the company is testing a pilot battery recycling plant in Kuppenheim, setting new standards for sustainable battery recycling solutions. The aim is to close the entire material loop, thereby making the future of electric mobility even more sustainable.

To reduce emissions at battery cell level, Mercedes‑Benz is also developing concepts that support decarbonisation and recyclate use in the housing and cell module components. The innovative battery system of the new Mercedes‑Benz MMA platform already incorporates aspects of “Design for Circularity”. Using recyclable materials with existing circular economies – such as steel – can significantly reduce the carbon footprint. To improve recycling efficiency, the components are designed according to the “Design for Circularity” approach. This means not using composite components or permanent (non-separable) joining techniques. Being able to disassemble and sort individual parts of a component can improve the quality of the recovered materials.

New ways of addressing biodiversity

Closed loops and resource conservation can also support biodiversity, water quality and safeguarding human rights in the supply chain. Mercedes‑Benz has carried out specific biodiversity analyses on selected components such as headlights, floor mats and door panels. The aim is to better understand and reduce the impact of material selection and the value chain on ecosystems and natural resources. Increasing the use of secondary materials and closing material loops can reduce the risks of environmental pollution and land use – two key levers for promoting biodiversity. The knowledge gained is flowing into the development of sustainable vehicle concepts and strengthening Mercedes‑Benz’s pioneering spirit in this increasingly important field.

Innovative selection of primary materials and material combinations

Mercedes‑Benz is consistently examining new solutions to reduce carbon footprint and conserve resources in the selection of primary materials and material combinations. An innovative material combination for the support connecting the centre console to the bodyshell is close to series production. It is a demanding component that must withstand high forces (in a side-on collision, for instance). And it must fit into a very confined space. The current component is a magnesium die-casting. This light metal offers weight benefits but has a high carbon footprint and is cost intensive.

As part of the Tomorrow XX technology programme, Mercedes‑Benz R&D has developed a centre-console support made from glass-fibre-reinforced polypropylene with steel inserts. This material combination has already proven itself in components that are subject to less stress. Extensive computer simulations helped establish the ideal mixture to meet the technical requirements for the support. The new material combination has the potential to reduce the carbon footprint of this part by over 90 percent. It also lowers the material and manufacturing costs and offers raw material independence compared to magnesium. Final testing prior to series production is currently underway.

The Tomorrow XX team has also found a new material combination for the upper and lower sections of the dashboard. Instead of different types of plastics, the component can be made entirely using plastics from the polyolefin family. The focus on one plastic family enables mechanical recycling of the entire structure – without separating the individual layers.

The team has taken a similar approach to material substitution for the underbody trim at the rear. The use of expanded polypropylene (EPP) was developed and validated in an earlier project. This innovation has been part of the portfolio ever since and can be used in new vehicle projects. EPP is a common material used for items like bicycle helmets and coolers. It is significantly lighter than the polypropylene used previously and reduces component weight by around 50 percent. This means halving the raw material and likewise reducing carbon emissions during production. The lower weight also reduces energy consumption over the entire vehicle use phase, which further improves the carbon footprint. EPP can be recycled up to eight times. It can then be transferred to the shredder residue used to make cladding.

The future of fossil-free plastics: a door module made from bio-based materials

The development of an innovative door module is a good example of how fossil-based raw materials can be avoided in future. The body and the cable-drive housing are made from bio-based polypropylene (PP) reinforced with recycled glass fibre. Bio-based PP is produced from renewable raw materials such as vegetable oils and used fats. In addition, the chemical industry is increasingly working on new production methods. These include replacing fossil-based raw materials with green methanol or green hydrogen. Bio-based PP offers similar properties to petrochemical-based PP but has a lower carbon footprint. The module’s guide rails are made from an aluminium alloy with a high scrap content, while its sliders are made from mechanically recycled polyamide (PA). The pulleys are made from the high-molecular-weight thermoplastic polyoxymethylene, which is produced from stored CO₂ using the mass balance process[3] (CO₂-to-plastic). The carbon footprint of the innovative door module is around 30 percent lower compared to today’s component.

This multi-part module demonstrates the importance of comparing and evaluating competing sustainability technologies. Fossil-free plastics will become increasingly important in future. It is already possible to do without fossil raw materials for many types of plastic. Alternative sources include CO₂, biomethane or biomass. However, the supply chain and economic viability of these alternatives are not yet ready for large-scale automotive production in many respects. To drive this transformation and accelerate the use of renewable carbon sources, Mercedes‑Benz became the first car manufacturer to join the Renewable Carbon Initiative (RCI) in 2025. The membership specifically supports the development and implementation of new sustainable plastic solutions – including those for components such as the door module.

BIONICAST® enables efficient use of material

The VISION EQXX marked the first use by Mercedes‑Benz of cast components developed using an innovative, bionic optimisation approach. It ensures that material is used only where it is needed. This makes a component lighter and more resource efficient. The method enables efficient component design for series development by taking into account production requirements at an early stage. The first components made with the BIONICAST® process are already in use in production vehicles, with more to follow. Compared to conventional components, the process can deliver up to 25-percent savings in weight and material.

Tomorrow XX delivers sustainability benefits to production at Mercedes‑Benz

Rethinking components and materials from scratch can help reduce the company’s consumption of raw materials at its own production facilities. Likewise, it can improve the efficiency of its processes, thus reducing energy consumption and contributing to decarbonisation. Mercedes‑Benz engineers consider all of this from the very start of the development process. These advances complement the huge strides already made in production. They include the ongoing ramp-up in the use of renewable energies at the company’s own production facilities. When it comes to circularity, Mercedes‑Benz also achieves an almost 100-percent recycling rate in production. Having already closed the loop for steel scrap, the company will do the same for aluminium scrap.

[1] Tomorrow XX is a technology programme that pushes at the limits of technical feasibility. What is shown here is a stage of development intended to represent the potential and approaches pursued by Mercedes-Benz. The technologies and components shown here are not ready for series production. This would only happen when all requirements for the component or concept are met. All figures are based on internal calculations.

[2] In the mass balance method, independent certification confirms that the quantities of fossil resources required for the end product have been replaced by renewable raw materials, recycled materials, or bio-based materials.

[3] In the mass balance process, independent certification confirms that the quantities of fossil resources required for the end product have been replaced by renewable raw materials, recyclates or bio-based materials.